1.What is the wind resistance level of heavy duty canopy 10×10?

Wind resistance ratings for heavy-duty canopies, including 10×10 models, may vary depending on the specific design, construction and materials used by the manufacturer. Typically, heavy-duty canopies are designed to withstand moderate to strong winds, but the exact level of wind resistance may vary from product to product.

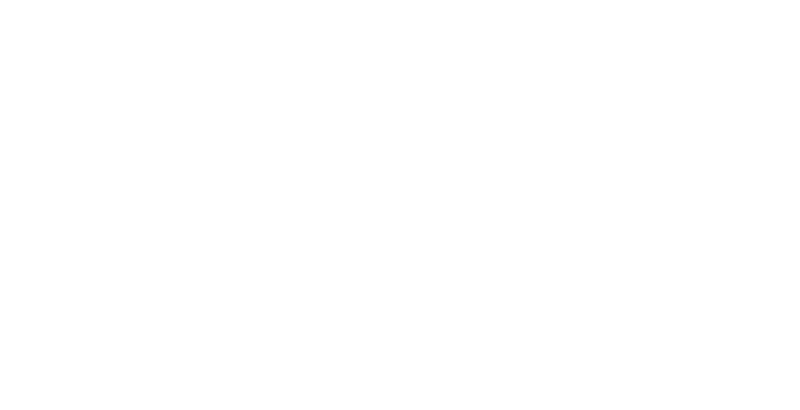

When researching or purchasing a heavy-duty canopy, it is crucial to check the product specifications provided by the manufacturer. Find information on wind resistance ratings, which can be expressed in terms of wind speed or the Beaufort scale. Some canopies are designed to withstand winds at a certain speed, for example ASAP Canopy’s heavy duty canopy 10×10 has a wind resistance of 30 mph / 50 km/h

Additionally, factors such as the frame construction of the canopy, the quality of materials used in the frame and canopy fabric, and the anchoring system are also taken into consideration. Proper setup and anchoring are critical to maximizing wind resistance. Many manufacturers provide guidelines for securing the canopy to ensure stability in windy conditions.

2.What is the wind resistance level of heavy duty canopy 10×10?

It’s great to know that ASAP Canopy supports the separate purchase of replacement parts for their heavy-duty canopy 10×10. This flexibility is beneficial for users who may need specific components over time due to wear and tear or other reasons.

If you require replacement parts for your heavy-duty canopy, you can follow the instructions provided by ASAP Canopy and reach out to them via email at info@asapcanopy.com. When contacting them, be sure to provide detailed information about the specific parts you need and any relevant details about your canopy to ensure that you receive the correct components.

Keep in mind that the availability of replacement parts is a valuable aspect of product support, allowing users to extend the lifespan of their canopy and address issues without having to purchase an entirely new unit.

If you have any specific questions about the replacement parts or the ordering process, contacting ASAP Canopy’s customer support is the best way to get accurate and personalized information.

3.Can the heavy duty canopy 10×10 be set up by one person?

Certainly, let’s delve into more detail about setting up a heavy-duty canopy, specifically a 10×10 model, by one person. Keep in mind that the specific design and features of canopies can vary between manufacturers, so these details are general considerations. For more accurate information, you may want to refer to the product manual or contact the manufacturer directly.

Here are some aspects to consider:

Frame Design:

- Check the type of frame the canopy has. Pop-up canopies are often designed for quick and easy setup. Look for features like a collapsible or telescoping frame, as these designs are generally more user-friendly for solo assembly.

Materials and Weight:

- Consider the weight of the canopy and its components. Lightweight materials, such as aluminum or lightweight steel, can make it easier for one person to handle during setup. However, heavy-duty canopies may still have substantial components, so it’s essential to assess your own strength and comfort level.

Assembly Mechanism:

- Understand the assembly mechanism. Some canopies feature a central hub where the frame components come together, making it simpler for one person to manage. Look for features like push-button connectors or locking mechanisms that are easy to manipulate alone.

Color-Coding or Markings:

- Check if the components are color-coded or marked for easy identification. This can significantly streamline the assembly process, reducing the chances of errors and making it more feasible for a single person.

Setup Time:

- Consider the estimated setup time provided by the manufacturer. A quicker setup time often indicates a more straightforward assembly process, and many manufacturers design their canopies with user-friendly features to facilitate solo setup.

Practice Setup:

- Before using the canopy for an event, it’s a good idea to practice setting it up at home. Familiarity with the process will make the actual setup at an event smoother.

Stability and Anchoring:

- While solo setup is important, ensure that the canopy is stable and properly anchored. Pay attention to the anchoring system, and follow the manufacturer’s guidelines to secure the canopy against wind and other elements.

User Feedback:

- Check customer reviews or testimonials for insights from other users who may have set up the same canopy model by themselves. They might share helpful tips or experiences.

Remember to always follow the manufacturer’s instructions and guidelines for setup and use. If you encounter any challenges or have specific questions about the setup process, don’t hesitate to reach out to the manufacturer’s customer support for assistance. They can provide detailed guidance based on the specific features of their product.

4.Is heavy duty canopy 10×10 waterproof and fireproof?

Waterproofing:

- Waterproof Ratings:

- Canopy fabrics often come with a waterproof rating measured in millimeters. For example, a fabric with a 1000mm waterproof rating means it can withstand the pressure of a 1000mm column of water before it starts to penetrate. Higher ratings generally indicate better waterproofing.

Seam Sealing:

- Check if the seams of the canopy are sealed. Taped seams or additional seam sealant enhance the waterproofing by preventing water from seeping through the stitched areas.

Material Type:

- The type of material used for the canopy fabric can affect its water resistance. Polyester and nylon are common materials, and some may have coatings or treatments to improve water repellency.

DWR Coating:

- Some canopies feature a durable water repellent (DWR) coating. This coating helps water bead up and roll off the fabric, enhancing its resistance to moisture.

Fire Resistance:

Material Composition:

- Canopy materials can vary, and some may have inherent fire-resistant properties. For instance, certain types of treated polyester may exhibit a degree of flame resistance.

Fire Retardant Treatment:

- Some canopies undergo specific fire retardant treatments. Look for information on whether the canopy fabric has been treated to resist ignition or slow down the spread of flames.

Certifications:

- Check if the canopy has certifications for fire resistance. Certifications from relevant safety standards organizations can provide assurance of a product’s fire-resistant qualities.

Manufacturer’s Specifications:

- Refer to the product specifications provided by the manufacturer. They often include details about the canopy’s fire resistance, if applicable.

Use Case Considerations:

- Understand the intended use of the canopy. While some canopies may have fire-resistant features, it’s essential to manage expectations—few products are entirely fireproof.

General Tips:

Maintenance: Follow the manufacturer’s recommendations for maintenance. Improper care can affect the longevity and performance of both waterproof and fire-resistant features.

Testing: If fire resistance is critical, inquire about any testing the canopy has undergone. Some manufacturers conduct tests to ensure their products meet specific safety standards.

Always prioritize safety and follow the manufacturer’s guidelines for proper use and care of the canopy. If you have specific questions about a particular 10×10 heavy-duty canopy, consider reaching out directly to the manufacturer for detailed and accurate information.

5.What kind of frame is heavy duty canopy 10×10?

The specific frame type used in heavy-duty canopy 10×10 models may vary by manufacturer and product line. Common frame materials include steel and aluminum, and there are different frame designs to consider. For example, ASAP Canopy uses a commercial-grade aluminum frame, and some businesses may have the following possibilities:

Steel Frame:

- Heavy-Duty Steel: Many heavy-duty canopies feature steel frames for durability and strength. The steel is often powder-coated to resist corrosion and enhance the frame’s longevity.

- Powder-Coated Steel: Powder coating provides an additional layer of protection against rust and weathering.

Aluminum Frame:

- Aluminum Alloy: Aluminum is known for being lightweight yet sturdy. Canopies with aluminum frames are often more portable and easier to handle during setup.

- Anodized Aluminum: Anodizing is an electrochemical process that adds a protective layer to the aluminum, improving corrosion resistance.

Frame Design:

- Pop-Up Design: Many 10×10 canopies have a pop-up or instant setup design. This often involves a collapsible frame that can be easily extended and locked into place.

- Telescoping Legs: Telescoping legs allow for adjustable height settings, providing flexibility in how the canopy is used.

Connection Mechanism:

- Push-Button Connectors: Some canopies use push-button connectors for ease of assembly. This design simplifies the process of extending and securing the frame components.

- Sliding and Locking Mechanisms: Frames may incorporate sliding and locking mechanisms for stability during use.

Frame Thickness:

- Thicker Poles: Heavy-duty canopies often have thicker frame poles for added strength and stability, especially important in adverse weather conditions.

Reinforcements:

- Cross-Brace Supports: Cross-brace supports add additional reinforcement to the frame, enhancing stability and structural integrity.

Durability Features:

- Reinforced Joints: Reinforced joints and corners contribute to the overall durability of the frame, preventing weak points that could be prone to failure.

5×5 Pop Up Tent

5×5 Pop Up Tent 6.5×6.5 Pop Up Tent

6.5×6.5 Pop Up Tent 10×10 Canopy Tent

10×10 Canopy Tent 10×15 Canopy Tent

10×15 Canopy Tent 10×20 Canopy Tent

10×20 Canopy Tent Canopy Options

Canopy Options Blank Canopy Top

Blank Canopy Top Canopy Top

Canopy Top Canopy Walls

Canopy Walls Canopy Side Skirt

Canopy Side Skirt Blank Canopy

Blank Canopy Blank Canopy Kit

Blank Canopy Kit

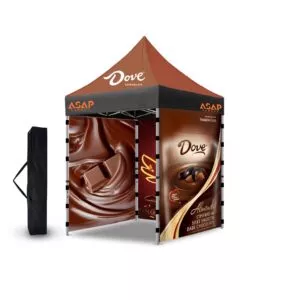

Inflatable Canopy Tents 10×10

Inflatable Canopy Tents 10×10 Inflatable Canopy Tents 13×13

Inflatable Canopy Tents 13×13 Inflatable Canopy Tents 16×16

Inflatable Canopy Tents 16×16 Inflatable Canopy Tents 20×20

Inflatable Canopy Tents 20×20 Inflatable Canopy Tents 23×23

Inflatable Canopy Tents 23×23 Inflatable Canopy Tents 26×26

Inflatable Canopy Tents 26×26 Inflatable Spider Tents

Inflatable Spider Tents Inflatable Dome Tents

Inflatable Dome Tents Inflatable Eclipse Tents

Inflatable Eclipse Tents Inflatable Party Tent

Inflatable Party Tent Inflatable Furniture

Inflatable Furniture Inflatable Pillar

Inflatable Pillar

Single Pole Star Tents

Single Pole Star Tents Double Pole Star Tents

Double Pole Star Tents

15FT Inflatable Arches

15FT Inflatable Arches 20FT Inflatable Arches

20FT Inflatable Arches 25FT Inflatable Arches

25FT Inflatable Arches 30FT Inflatable Arches

30FT Inflatable Arches 40FT Inflatable Arches

40FT Inflatable Arches 50FT Inflatable Arches

50FT Inflatable Arches Custom Constant Arches

Custom Constant Arches Custom Sealed Arches

Custom Sealed Arches

Fitted Table Covers

Fitted Table Covers Stretch-Fit Table Covers

Stretch-Fit Table Covers Loose Table Throws

Loose Table Throws Cross-Over Stretch-Fit Table Cover

Cross-Over Stretch-Fit Table Cover Round Stretch-Fit Table Cover

Round Stretch-Fit Table Cover Blank Table Throws

Blank Table Throws 3-Sided Loose Table Throw

3-Sided Loose Table Throw Round Fitted Table Covers

Round Fitted Table Covers Table Runners

Table Runners Square Table Covers

Square Table Covers

Feather Flags

Feather Flags Blade Flags

Blade Flags Feather Banner

Feather Banner Blade Banner

Blade Banner Teardrop Flags

Teardrop Flags Teardrop Banner

Teardrop Banner Rectangle Flags

Rectangle Flags Rectangle Banner

Rectangle Banner Mesh Event Banners

Mesh Event Banners Pop Out Banner Horizontal

Pop Out Banner Horizontal Pop-Out Banner Vertical

Pop-Out Banner Vertical

Trade Show Display

Trade Show Display Trade Show Display Kit

Trade Show Display Kit Pop Up Trade Show Display

Pop Up Trade Show Display Pop Up Trade Show Display Deluxe Kit

Pop Up Trade Show Display Deluxe Kit Pop Up Trade Show Display Kit

Pop Up Trade Show Display Kit TableTop Displays Kit

TableTop Displays Kit Pop Up Tabletop Display Kit

Pop Up Tabletop Display Kit Pop Up Tabletop Display

Pop Up Tabletop Display Tabletop Display

Tabletop Display Straight Trade Show Exhibit Booth

Straight Trade Show Exhibit Booth Banner Stand

Banner Stand

Tent Accessories

Tent Accessories Flag Accessories

Flag Accessories Arch Accessories

Arch Accessories Trade Show Accessories

Trade Show Accessories