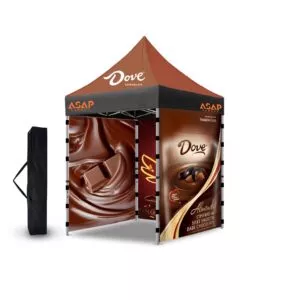

What material is used for the tent fabric of the logo 10×10 tent, and how well does it perform in various weather conditions?

I don’t have specific information about a logo 10×10 tent as it could refer to a tent from a particular brand or vendor. However, I can provide general information about tent materials and their performance in various weather conditions.

Tent fabric for commercial-grade tents, including those used for branding and logos, often features durable and weather-resistant materials. Common materials used for tent fabric include:

1.Polyester:

Polyester is a popular choice for tent fabric due to its durability, lightweight nature, and resistance to UV rays. Coated polyester is often used for added water resistance.

2.Polyethylene (PE):

PE is commonly used for tent canopies and sidewalls. It is waterproof and can provide good protection against rain.

3.Vinyl:

Heavy-duty vinyl is known for its robustness and excellent waterproofing properties. Vinyl-coated fabrics are often used in high-quality commercial tents.

The performance of the tent fabric in various weather conditions depends on factors such as the type of coating, thickness of the material, and overall construction. Here’s a general overview:

4.Rain:

Coated polyester, polyethylene, and vinyl are effective in repelling water, making them suitable for rainy conditions. Look for tents with waterproof seams and reinforced corners for added protection.

5.Sun (UV Exposure):

UV-resistant coatings on polyester and vinyl help prevent fading and deterioration caused by prolonged exposure to sunlight. This is important for maintaining the appearance and longevity of the tent.

6.Wind:

The frame design and anchoring system play a crucial role in wind resistance. While the fabric itself can withstand wind, it’s important to properly secure the tent to the ground using stakes or weights.

7.Temperature Extremes:

Tent fabrics are generally designed to withstand a range of temperatures. However, it’s essential to follow the manufacturer’s guidelines regarding temperature limits to ensure the tent’s integrity.

For specific information about the logo 10×10 tent, including the fabric material and its performance in various weather conditions, I recommend checking the product details provided by the manufacturer or vendor. They should offer information on the specific materials used and any additional features that contribute to the tent’s durability and weather resistance.

The materials used in lightweight 10×10 canopies play a crucial role in determining their overall weight. Here are common materials employed in the construction of lightweight canopies and their contributions:

1.Frame Materials:

Aluminum: Aluminum is a popular choice for lightweight canopy frames. It offers a good balance between strength and weight. Anodized aluminum is often used to enhance durability and corrosion resistance.

Fiberglass: Fiberglass frames are lightweight and flexible, making them suitable for easy assembly. However, fiberglass may not be as durable as aluminum in certain conditions.

Steel: Some lightweight canopies feature steel frames. While steel is heavier than aluminum, manufacturers often use thinner steel tubing to reduce weight without sacrificing too much strength.

2.Canopy Fabric:

Polyester: Lightweight canopies commonly use polyester fabric. It is known for its lightness, durability, and resistance to UV rays. Coated polyester can provide additional water resistance.

Nylon: Nylon is another lightweight and durable fabric option. It is often used in conjunction with coatings to enhance water resistance.

Polyethylene (PE): PE is a lightweight material often used for canopy sidewalls. It provides basic water resistance and is easy to handle.

3.Connectors and Joints:

Plastic: Lightweight canopies often feature plastic connectors and joints. While not as durable as metal, high-quality plastics are chosen to maintain strength while reducing overall weight.

4.Fasteners:

Nylon Straps or Velcro: Lightweight canopies use lightweight fastening systems such as nylon straps or Velcro. These materials contribute to ease of use and portability.

5.Carry Bag or Case:

Polyester or Nylon: The carry bag or case is usually made of lightweight materials such as polyester or nylon, contributing minimally to the overall weight of the canopy.

It’s important to note that the overall weight of a 10×10 canopy is influenced not only by the materials used but also by the design, construction, and any additional features included. Manufacturers aim to strike a balance between weight, durability, and functionality to create canopies that are easy to transport and set up while still providing adequate protection and stability. When considering a specific 10×10 canopy, it’s advisable to check the product specifications provided by the manufacturer for details on materials and weight.

What safety features are incorporated into the design of the large event tents for sale to ensure secure and stable installations?

The safety features incorporated into large event tents for sale are crucial to ensure secure and stable installations, especially for events with a significant number of attendees. While specific features can vary among manufacturers and models, here are common safety considerations:

1.Structural Integrity:

High-Quality Materials: Large event tents are often constructed using durable and robust materials such as heavy-duty aluminum or steel for the frame components. The choice of materials contributes to the overall strength and structural integrity of the tent.

Reinforced Joints: The joints and connectors of the tent frame are reinforced to enhance stability. This is particularly important in preventing structural failures during adverse weather conditions.

2.Anchoring Systems:

Sturdy Stakes or Anchors: Large event tents come with robust anchoring systems, including stakes or anchors, to secure the tent to the ground. Proper installation of anchors is critical for stability, especially in windy conditions.

Weighted Systems: Some tents offer the option to use weighted systems, such as sandbags or water barrels, to anchor the tent on hard surfaces where traditional stakes cannot be used.

3.Weather Resistance:

Wind Resistance: Large event tents are designed with wind resistance in mind. The tent fabric and frame construction are engineered to withstand varying wind speeds. Manufacturers often provide wind ratings to guide users on the tent’s safe usage in specific conditions.

Water Resistance: The tent fabric is treated to be water-resistant or waterproof, providing protection against rain. Sealed seams and reinforced corners further enhance water resistance.

4.Fire Safety:

Fire-Resistant Materials: Many large event tents are made from fire-resistant materials to comply with safety regulations. This is crucial for events involving large crowds.

Exit Options: Tents are designed with multiple entry and exit points to facilitate safe and quick evacuation in case of emergencies.

5.User-Friendly Setup:

Clear Setup Instructions: Manufacturers provide clear and detailed setup instructions to ensure proper installation. This includes guidelines for securing the tent and establishing a safe and stable structure.

Color-Coding or Labeling: Some tents feature color-coded or labeled components to assist users in assembling the tent correctly. This reduces the risk of errors during setup.

6.Certifications and Compliance:

Safety Certifications: Reputable manufacturers often subject their large event tents to rigorous testing to obtain safety certifications. These certifications ensure that the tent complies with industry standards for safety and performance.

Local Regulations: Tents should adhere to local regulations and building codes. Manufacturers may provide documentation to help users understand the tent’s compliance with relevant standards.

Can the instant tent be easily taken down and packed away, and does it come with a convenient carrying bag?

The ease of taking down and packing away an instant tent can vary depending on the specific model and brand. However, many instant tents are designed with user-friendly features to simplify the process of disassembly and storage. Here are common characteristics associated with instant tents:

1.Pop-Up Design:

Instant tents often feature a pop-up or quick-pitch design, allowing for swift and straightforward setup and takedown. The frame typically unfolds and locks into place with minimal effort.

2.Foldable Frame:

Instant tents are designed with collapsible frames that can be easily folded or collapsed. This is a key feature that contributes to the quick takedown of the tent.

3.Hub Systems:

Some instant tents incorporate hub systems that simplify the assembly and disassembly process. These systems use interconnected hubs to speed up the setup and takedown of the tent.

4.Color-Coded Components:

To enhance user convenience, some instant tents come with color-coded components. This visual guidance makes it easier for users to identify and match parts during both setup and takedown.

5.Centralized Disconnect Points:

The design often includes centralized disconnect points where users can release the tension or locking mechanisms, allowing the frame to collapse or fold easily.

6.Release Buttons or Levers:

Instant tents may feature release buttons or levers that allow users to quickly disengage specific sections of the frame, facilitating a smooth takedown process.

7.Carrying Bag:

Many instant tents come with a convenient carrying bag. This bag is designed to accommodate the folded tent, poles, stakes, and sometimes the rainfly. A properly sized and well-designed carrying bag adds to the portability of the tent.

8.Compact Folded Size:

Instant tents are generally designed to fold into a compact size, making them easy to transport and store. The compact folded form contributes to the convenience of packing and carrying the tent.

It’s important to note that while many instant tents are designed for quick setup and takedown, individual experiences may vary based on the user’s familiarity with the tent and the specific design of the model. Reading the manufacturer’s instructions and practicing the setup and takedown before your camping trip can help ensure a smooth experience.

When choosing an instant tent, consider user reviews, product specifications, and any additional features that contribute to the ease of both setup and takedown. The inclusion of a well-designed carrying bag can be an essential factor for convenient transportation and storage.

How easy is it to set up the One Push Canopy 10×10, and does it require any special tools?

As of my last knowledge update in January 2022, I don’t have specific information about a product called the “One Push Canopy 10×10.” However, the name suggests that it might be a pop-up canopy with a one-push or instant setup feature, which is common among many portable canopy tents.

Generally, pop-up canopies are designed to be user-friendly and do not require special tools for assembly. They typically come with a collapsible frame that uses a push-button mechanism for quick and easy setup. Here are the general steps for setting up a typical 10×10 one-push canopy:

1.Unpack the Canopy:

Remove the canopy tent from its storage bag and lay out all the components.

2.Extend the Frame:

Grasp the frame at the center and extend it outward until fully open. Most pop-up canopies have a concertina-style frame that unfolds.

3.Lock the Frame:

Once the frame is fully extended, the push-button mechanism should engage automatically to lock the frame in place. Some models may require you to manually lock each leg section into position.

4.Adjust Height (if applicable):

If your canopy has adjustable height settings, set the desired height by adjusting the telescopic legs. Lock them into place to secure the chosen height.

5.Attach Canopy Fabric:

With the frame fully extended, drape the canopy fabric over the frame. Secure the corners of the fabric to the frame using the attached fasteners or straps.

6.Stake or Weigh Down (if necessary):

If using the canopy outdoors, secure it by staking down the corners or using weights to prevent it from being lifted by the wind.

Instructions for setting up a specific canopy model should be provided in the product manual that comes with the tent. Always refer to the manufacturer’s instructions for the most accurate and model-specific guidance.

In general, pop-up canopies are designed to be user-friendly and can be set up by one person. No special tools are typically required, as the frame components are designed to lock into place with minimal effort. If you have access to the specific product manual or instructional guide for the “One Push Canopy 10×10,” it will provide the most accurate and detailed information for assembly.

What is the printing method used for the logo pop up canopy, and how durable is the logo imprint?

The printing method used for logo pop up canopy often depends on the manufacturer, the type of canopy, and the customization options offered. Two common printing methods for canopy logos are:

1.Screen Printing:

Process: Screen printing involves using a mesh screen stencil to transfer ink onto the canopy fabric. Each color in the logo requires a separate screen.Durability: Screen printing is generally durable and provides vibrant colors. However, over time and with frequent use, the print may show signs of wear, especially if subjected to harsh weather conditions or abrasion.

2.Digital Printing:

Process: Digital printing allows for high-resolution, full-color printing directly onto the canopy fabric using digital technology. It is suitable for intricate designs and detailed logos.Durability: The durability of digital printing varies based on the quality of the ink and the fabric. UV-resistant and fade-resistant inks can enhance the longevity of the imprint. While digital printing can be durable, it may not withstand abrasion as well as some other methods.

3.Factors Affecting Logo Imprint Durability:

Fabric Quality:The type and quality of the canopy fabric play a significant role in how well the logo imprint lasts. High-quality, durable fabrics are less prone to fading and wear.Ink Quality:The quality of the ink used in the printing process is crucial. UV-resistant, waterproof, and fade-resistant inks contribute to a more durable logo imprint.Usage Conditions:The environment in which the canopy is used affects the durability of the logo. Exposure to harsh weather conditions, prolonged sunlight, and frequent setup and takedown can impact the longevity of the print.Care and Maintenance:Proper care, cleaning, and storage of the canopy can contribute to the durability of the logo imprint. Following manufacturer guidelines for maintenance is essential.Additional Coatings or Treatments:Some logo pop up canopy may come with additional coatings or treatments that enhance durability. Water-resistant coatings and protective layers can help protect the logo imprint.It’s advisable to check with the canopy manufacturer or supplier for specific details about the printing method used for logos, the quality of inks, and any additional treatments that may contribute to durability. Additionally, customer reviews and testimonials can provide insights into the long-term performance of logo imprints on specific canopy models.

Is the one person pop up canopy 10×10 designed to provide UV protection, and if so, what level of protection does it offer?

The level of UV protection provided by one person pop up canopy 10×10 depends on the specific design and materials used in its construction. Canopies, especially those designed for outdoor use, often incorporate materials that offer some degree of UV protection. However, the extent of protection can vary among different canopy models and brands.

When considering a canopy for UV protection, here are some factors to keep in mind:

1.Material Composition:

Canopy materials such as polyester or polyethylene may inherently provide some UV resistance. Look for canopies made from materials with UV-blocking properties.

2.UPF Rating:

Some canopies come with a Ultraviolet Protection Factor (UPF) rating, which indicates the level of UV protection provided by the fabric. A higher UPF rating signifies greater UV-blocking capabilities.

3.Coatings and Treatments:

Some canopies may feature special coatings or treatments that enhance their UV resistance. Water-resistant coatings or UV-blocking treatments can contribute to better protection against the sun’s harmful rays.

4.Color Choice:

The color of the canopy can affect its UV protection capabilities. Darker colors tend to absorb more sunlight and may provide better UV protection than lighter colors.

5.Manufacturer Specifications:

Check the product specifications and information provided by the manufacturer. Reliable canopy manufacturers often include details about the level of UV protection their products offer.

6.Additional Accessories:

Some one person pop up canopy 10×10 may be compatible with additional accessories, such as sidewalls or sunscreens, which can enhance UV protection by providing additional coverage.

To determine the specific UV protection level of a canopy, look for information provided by the manufacturer. This information is typically included in product descriptions, user manuals, or on the product packaging. UPF ratings, if available, are a useful indicator of the canopy’s ability to block ultraviolet rays.

It’s important to note that even if a canopy provides UV protection, using additional sun safety measures, such as sunscreen and appropriate clothing, is advisable when spending extended periods outdoors. Keep in mind that product designs and specifications may change, so it’s recommended to check the latest information from the manufacturer or product documentation for the most accurate details.

5×5 Pop Up Tent

5×5 Pop Up Tent 6.5×6.5 Pop Up Tent

6.5×6.5 Pop Up Tent 10×10 Canopy Tent

10×10 Canopy Tent 10×15 Canopy Tent

10×15 Canopy Tent 10×20 Canopy Tent

10×20 Canopy Tent Canopy Options

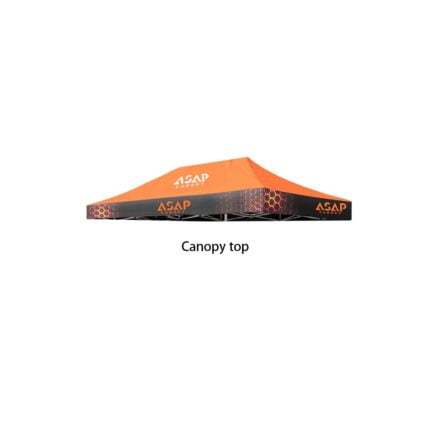

Canopy Options Blank Canopy Top

Blank Canopy Top Canopy Top

Canopy Top Canopy Walls

Canopy Walls Canopy Side Skirt

Canopy Side Skirt Blank Canopy

Blank Canopy Blank Canopy Kit

Blank Canopy Kit

Inflatable Canopy Tents 10×10

Inflatable Canopy Tents 10×10 Inflatable Canopy Tents 13×13

Inflatable Canopy Tents 13×13 Inflatable Canopy Tents 16×16

Inflatable Canopy Tents 16×16 Inflatable Canopy Tents 20×20

Inflatable Canopy Tents 20×20 Inflatable Canopy Tents 23×23

Inflatable Canopy Tents 23×23 Inflatable Canopy Tents 26×26

Inflatable Canopy Tents 26×26 Inflatable Spider Tents

Inflatable Spider Tents Inflatable Dome Tents

Inflatable Dome Tents Inflatable Eclipse Tents

Inflatable Eclipse Tents Inflatable Party Tent

Inflatable Party Tent Inflatable Furniture

Inflatable Furniture Inflatable Pillar

Inflatable Pillar

Single Pole Star Tents

Single Pole Star Tents Double Pole Star Tents

Double Pole Star Tents

15FT Inflatable Arches

15FT Inflatable Arches 20FT Inflatable Arches

20FT Inflatable Arches 25FT Inflatable Arches

25FT Inflatable Arches 30FT Inflatable Arches

30FT Inflatable Arches 40FT Inflatable Arches

40FT Inflatable Arches 50FT Inflatable Arches

50FT Inflatable Arches Custom Constant Arches

Custom Constant Arches Custom Sealed Arches

Custom Sealed Arches

Fitted Table Covers

Fitted Table Covers Stretch-Fit Table Covers

Stretch-Fit Table Covers Loose Table Throws

Loose Table Throws Cross-Over Stretch-Fit Table Cover

Cross-Over Stretch-Fit Table Cover Round Stretch-Fit Table Cover

Round Stretch-Fit Table Cover Blank Table Throws

Blank Table Throws 3-Sided Loose Table Throw

3-Sided Loose Table Throw Round Fitted Table Covers

Round Fitted Table Covers Table Runners

Table Runners Square Table Covers

Square Table Covers

Feather Flags

Feather Flags Blade Flags

Blade Flags Feather Banner

Feather Banner Blade Banner

Blade Banner Teardrop Flags

Teardrop Flags Teardrop Banner

Teardrop Banner Rectangle Flags

Rectangle Flags Rectangle Banner

Rectangle Banner Mesh Event Banners

Mesh Event Banners Pop Out Banner Horizontal

Pop Out Banner Horizontal Pop-Out Banner Vertical

Pop-Out Banner Vertical

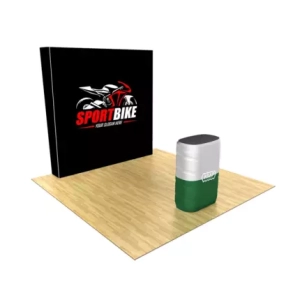

Trade Show Display

Trade Show Display Trade Show Display Kit

Trade Show Display Kit Pop Up Trade Show Display

Pop Up Trade Show Display Pop Up Trade Show Display Deluxe Kit

Pop Up Trade Show Display Deluxe Kit Pop Up Trade Show Display Kit

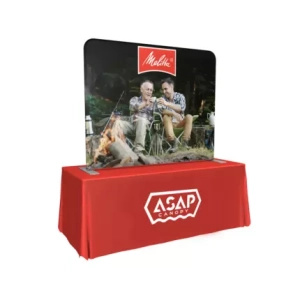

Pop Up Trade Show Display Kit TableTop Displays Kit

TableTop Displays Kit Pop Up Tabletop Display Kit

Pop Up Tabletop Display Kit Pop Up Tabletop Display

Pop Up Tabletop Display Tabletop Display

Tabletop Display Straight Trade Show Exhibit Booth

Straight Trade Show Exhibit Booth Banner Stand

Banner Stand

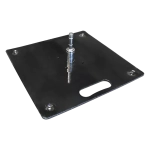

Tent Accessories

Tent Accessories Flag Accessories

Flag Accessories Arch Accessories

Arch Accessories Trade Show Accessories

Trade Show Accessories