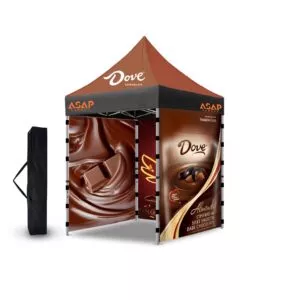

The Art of Make Custom Canopy Tents: ASAP CANOPY’s Approach

1. The Foundation: Selecting Premium Materials

At ASAP CANOPY, we believe that exceptional Make Custom Canopy Tents start with top-quality materials. Our commitment to excellence begins at the very foundation of our products.

Frame Selection

We primarily use aircraft-grade aluminum for our frames, chosen for its:

– Lightweight nature

– Exceptional durability

– Resistance to rust and corrosion

For specific applications, we also offer steel frames, which provide:

– Enhanced stability in windy conditions

– Cost-effective options for less frequent use

Fabric Choices

Our canopy fabrics are carefully selected to ensure:

– Weather resistance

– Color vibrancy

– Longevity

We offer various fabric options, including:

– 600D polyester: Our standard, durable option

– 900D polyester: For enhanced weather protection

– Vinyl: Ideal for heavy-duty, waterproof applications

Each fabric undergoes rigorous testing to meet our high standards for quality and performance.

2. Design and Customization Process

Creating a Make Custom Canopy Tents that perfectly represents your brand is a collaborative effort between our design team and our clients.

Initial Consultation

– We discuss your specific needs and vision

– Our team provides expert advice on design options

– We consider factors like event type, frequency of use, and budget

Digital Mock-ups

– Our designers create detailed digital renderings

– Clients can visualize the final product before production

– Multiple revisions are offered to ensure complete satisfaction

Color Matching

– We use advanced color matching technology

– Ensure brand colors are accurately represented

– Provide physical color swatches for client approval

3. Cutting-Edge Printing Techniques

The quality of printing can make or break a Make Custom Canopy Tents. At ASAP CANOPY, we employ state-of-the-art printing methods to ensure your design stands out.

Dye Sublimation Printing

– Produces vibrant, long-lasting colors

– Ideal for complex designs and gradients

– Resistant to fading and weathering

UV Printing

– Offers excellent durability for outdoor use

– Provides sharp, clear images

– Environmentally friendly option

Large Format Printing

– Allows for seamless, full-coverage designs

– Ensures consistent color across large surfaces

– Enables intricate detailing on larger tents

Our printing process includes multiple quality checks to guarantee color accuracy and print quality.

4. Precision Cutting and Assembly

After printing, the fabrication process moves to cutting and assembly, where precision is key.

Computer-Aided Cutting

– Utilizes advanced CNC cutting machines

– Ensures exact measurements and clean edges

– Minimizes material waste

Expert Sewing and Assembly

– Skilled technicians handle the sewing process

– Use heavy-duty, weather-resistant threads

– Reinforce stress points for enhanced durability

Frame Assembly

– Each frame is carefully assembled and tested

– All moving parts are lubricated for smooth operation

– Safety checks are performed to ensure stability

5. Quality Control Measures

Quality is at the heart of everything we do at ASAP CANOPY. Our rigorous quality control process ensures that every Make Custom Canopy Tents meets our high standards.

Multi-Point Inspection

– Visual inspection of printed graphics

– Structural integrity checks on frames

– Functionality tests on all moving parts

Weather Resistance Testing

– Canopies are subjected to simulated weather conditions

– Tests include water resistance and UV exposure

– Ensures performance in various outdoor environments

Durability Stress Tests

– Frames undergo repeated setup and takedown cycles

– Fabric is tested for tear resistance and color fastness

– Ensures longevity even with frequent use

6. Packaging and Shipping

The final step in our fabrication process is preparing your Make Custom Canopy Tents for safe transport.

Custom Packaging

– Heavy-duty carry bags designed for easy transport

– Protective padding for frame components

– Clear instructions included for setup and takedown

Shipping Options

– Standard ground shipping available

– Expedited options for time-sensitive orders

– International shipping capabilities

Tracking and Insurance

– Real-time tracking provided for all shipments

– Insurance options available for added peace of mind

– Dedicated support for any shipping-related queries

7. After-Sales Support and Warranty

Our commitment to quality extends beyond the sale, with comprehensive after-sales support and warranty coverage.

Customer Support

– Dedicated support team available for setup assistance

– Troubleshooting guidance for any issues

– Maintenance advice to prolong tent life

Warranty Coverage

– Frame warranty: 5 years to lifetime, depending on model

– Fabric warranty: 1-3 years, based on material type

– Easy claim process for warranty issues

Repair and Replacement Services

– On-site repair options for minor issues

– Replacement parts readily available

– Full replacement for major defects covered under warranty

8. Continuous Innovation and Improvement

At ASAP CANOPY, we’re always looking for ways to enhance our Make Custom Canopy Tents and fabrication process.

Material Research

– Ongoing testing of new fabric technologies

– Exploration of eco-friendly material options

– Collaboration with suppliers for exclusive materials

Production Efficiency

– Regular updates to manufacturing equipment

– Implementation of lean production techniques

– Staff training on latest industry best practices

Design Capabilities

– Investment in advanced design software

– Expansion of customization options

– Development of new tent styles and features

9. Sustainability Initiatives

We recognize the importance of environmental responsibility in our manufacturing processes.

Eco-Friendly Practices

– Use of water-based, non-toxic inks

– Implementation of fabric recycling programs

– Energy-efficient production facilities

Sustainable Packaging

– Reduction of plastic use in packaging

– Use of recycled and recyclable materials

– Optimization of packaging sizes to reduce waste

Long-Term Durability

– Focus on creating long-lasting products to reduce waste

– Repair services to extend product life

– Education on proper care and maintenance for customers

Make Custom Canopy Tents Ways Conclusion

The process of Make Custom Canopy Tents at ASAP CANOPY is a meticulous journey from concept to completion. Our commitment to quality, innovation, and customer satisfaction drives every step of our fabrication process. Whether you’re looking for a single custom tent or a large-scale order, our team is dedicated to delivering exceptional products that meet your unique needs and exceed your expectations.

By choosing ASAP CANOPY for your Make Custom Canopy Tent needs, you’re not just getting a product – you’re investing in a legacy of quality, creativity, and unparalleled craftsmanship. We invite you to experience the ASAP CANOPY difference and see how our Make Custom Canopy Tents can elevate your brand and event presence.

5×5 Pop Up Tent

5×5 Pop Up Tent 6.5×6.5 Pop Up Tent

6.5×6.5 Pop Up Tent 10×10 Canopy Tent

10×10 Canopy Tent 10×15 Canopy Tent

10×15 Canopy Tent 10×20 Canopy Tent

10×20 Canopy Tent Canopy Options

Canopy Options Blank Canopy Top

Blank Canopy Top Canopy Top

Canopy Top Canopy Walls

Canopy Walls Canopy Side Skirt

Canopy Side Skirt Blank Canopy

Blank Canopy Blank Canopy Kit

Blank Canopy Kit

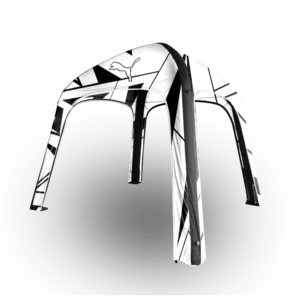

Inflatable Canopy Tents 10×10

Inflatable Canopy Tents 10×10 Inflatable Canopy Tents 13×13

Inflatable Canopy Tents 13×13 Inflatable Canopy Tents 16×16

Inflatable Canopy Tents 16×16 Inflatable Canopy Tents 20×20

Inflatable Canopy Tents 20×20 Inflatable Canopy Tents 23×23

Inflatable Canopy Tents 23×23 Inflatable Canopy Tents 26×26

Inflatable Canopy Tents 26×26 Inflatable Spider Tents

Inflatable Spider Tents Inflatable Dome Tents

Inflatable Dome Tents Inflatable Eclipse Tents

Inflatable Eclipse Tents Inflatable Party Tent

Inflatable Party Tent Inflatable Furniture

Inflatable Furniture Inflatable Pillar

Inflatable Pillar

15FT Inflatable Arches

15FT Inflatable Arches 20FT Inflatable Arches

20FT Inflatable Arches 25FT Inflatable Arches

25FT Inflatable Arches 30FT Inflatable Arches

30FT Inflatable Arches 40FT Inflatable Arches

40FT Inflatable Arches 50FT Inflatable Arches

50FT Inflatable Arches Custom Constant Arches

Custom Constant Arches Custom Sealed Arches

Custom Sealed Arches

Fitted Table Covers

Fitted Table Covers Stretch-Fit Table Covers

Stretch-Fit Table Covers Loose Table Throws

Loose Table Throws Cross-Over Stretch-Fit Table Cover

Cross-Over Stretch-Fit Table Cover Round Stretch-Fit Table Cover

Round Stretch-Fit Table Cover Blank Table Throws

Blank Table Throws 3-Sided Loose Table Throw

3-Sided Loose Table Throw Round Fitted Table Covers

Round Fitted Table Covers Table Runners

Table Runners Square Table Covers

Square Table Covers

Single Pole Star Tents

Single Pole Star Tents Double Pole Star Tents

Double Pole Star Tents

Feather Flags

Feather Flags Feather Banner

Feather Banner Blade Flags

Blade Flags Blade Banner

Blade Banner Teardrop Flags

Teardrop Flags Teardrop Banner

Teardrop Banner Rectangle Flags

Rectangle Flags Rectangle Banner

Rectangle Banner Mesh Event Banners

Mesh Event Banners Pop Out Banner Horizontal

Pop Out Banner Horizontal Pop-Out Banner Vertical

Pop-Out Banner Vertical

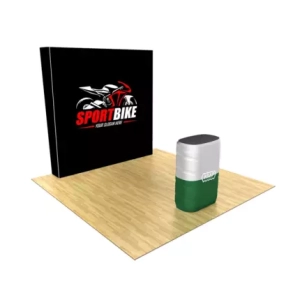

Trade Show Display

Trade Show Display Trade Show Display Kit

Trade Show Display Kit Pop Up Trade Show Display

Pop Up Trade Show Display Pop Up Trade Show Display Deluxe Kit

Pop Up Trade Show Display Deluxe Kit Pop Up Trade Show Display Kit

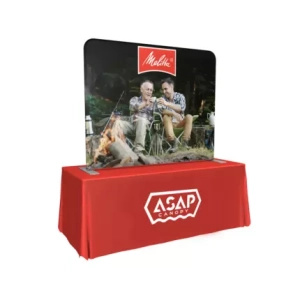

Pop Up Trade Show Display Kit TableTop Displays Kit

TableTop Displays Kit Pop Up Tabletop Display Kit

Pop Up Tabletop Display Kit Pop Up Tabletop Display

Pop Up Tabletop Display Tabletop Display

Tabletop Display Straight Trade Show Exhibit Booth

Straight Trade Show Exhibit Booth Banner Stand

Banner Stand

Flag Accessories

Flag Accessories Arch Accessories

Arch Accessories