Unveiling the Craft: The Meticulous Production Process of Inflatable Arches

The Art and Science Behind Inflatable Arch Manufacturing

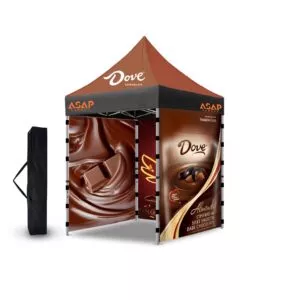

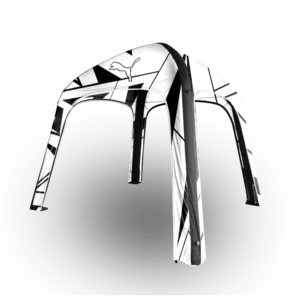

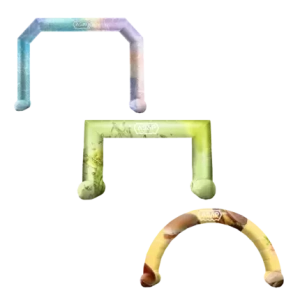

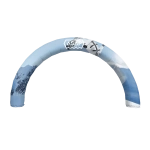

In the dynamic world of event marketing and celebrations, inflatable arches stand as towering symbols of welcome, achievement, and brand presence. At ASAP CANOPY, we’ve mastered the intricate process of creating these eye-catching structures, blending cutting-edge technology with time-honored craftsmanship. This article will take you behind the scenes, revealing the meticulous steps we take to produce inflatable arches that are not just visually stunning, but also durable and versatile.

Material Selection: The Foundation of Quality

The Crucial Role of Fabric Choice

The journey of creating a superior inflatable arch begins with selecting the right materials. At ASAP CANOPY, we primarily utilize two types of fabrics, each chosen for its unique properties and suitability for different applications.

600 Denier Polyester Fabric: Strength Meets Lightness

600 denier polyester fabric is a cornerstone of our inflatable arch production. This material offers a perfect balance of durability and weight, making it ideal for a wide range of events. Here’s why we love working with this fabric:

- Robust Resilience: The high denier count translates to exceptional tear and abrasion resistance.

- Weather Warriors: These arches can brave the elements, from scorching sun to unexpected showers.

- Featherlight Feel: Despite its strength, the fabric remains surprisingly lightweight, easing transportation and setup.

- Print-Perfect Surface: It provides an excellent canvas for our heat transfer printing process, ensuring vibrant, long-lasting graphics.

PVC Fabric: When Waterproofing is Paramount

For scenarios where moisture resistance is critical, we turn to PVC fabric. This material excels in several areas:

- Waterproof Wonder: PVC fabric offers superior protection against rain and humidity.

- Shape Shifter: It’s the go-to choice for unique, complex arch designs.

- Size Specialist: When we’re crafting larger-than-life inflatable arches, PVC fabric is our trusted ally.

- Silk Screen Superstar: This material pairs perfectly with our silk screen printing technique.

The ASAP CANOPY Difference: Beyond Basic Materials

While the choice between 600 denier polyester and PVC fabric forms the foundation of our inflatable arches, our commitment to quality doesn’t stop there. We continuously research and test new materials and coatings to enhance the performance of our products. This includes:

- UV-Resistant Treatments: To ensure colors stay vibrant even after prolonged sun exposure.

- Fire-Retardant Additives: For added safety in various event settings.

- Anti-Microbial Coatings: Particularly useful for arches used in medical or food-related events.

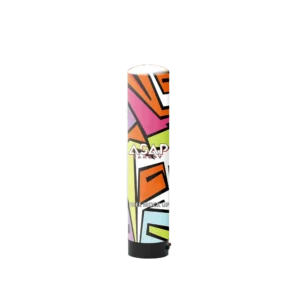

Printing Technologies: Where Creativity Meets Precision

The visual impact of an inflatable arch can make or break an event’s ambiance. That’s why at ASAP CANOPY, we employ state-of-the-art printing technologies to bring our clients’ visions to life.

Heat Transfer Printing: Vibrant Visuals on Polyester

For our 600 denier polyester fabric arches, we utilize heat transfer printing. This advanced technique offers several advantages:

- Color Brilliance: Achieve stunning, photo-quality images with rich, saturated colors.

- Detail Mastery: Capture intricate designs and fine text with razor-sharp precision.

- Durability Defined: The printed designs become an integral part of the fabric, resisting fading and wear.

- Eco-Friendly Option: Many heat transfer inks are water-based, reducing environmental impact.

The Heat Transfer Process: A Step-by-Step Guide

- Design Creation: Our graphic designers work closely with clients to create the perfect visual concept.

- Digital Printing: The design is printed onto special transfer paper using high-quality, durable inks.

- Heat Application: Using precisely controlled heat and pressure, we transfer the design onto the polyester fabric.

- Cooling and Setting: The fabric is allowed to cool, setting the design permanently into the material.

Silk Screen Printing: PVC’s Perfect Partner

When working with PVC fabric, we turn to the time-tested technique of silk screen printing. This method shines in several ways:

- Unmatched Durability: Silk screened designs can withstand heavy use and frequent cleaning.

- Opacity Excellence: Achieve solid, vibrant colors even on darker base materials.

- Special Effect Mastery: Easily incorporate metallic, glitter, or glow-in-the-dark inks for unique effects.

- Large-Scale Efficiency: Ideal for producing multiple arches with identical designs quickly.

The Silk Screen Process: Artistry in Action

- Screen Preparation: A mesh screen is coated with light-sensitive emulsion.

- Stencil Creation: The design is printed onto the screen, creating a stencil when exposed to light.

- Color Application: Ink is pushed through the stencil onto the PVC fabric using a squeegee.

- Drying and Curing: The printed fabric is carefully dried and cured to ensure long-lasting results.

Beyond Printing: The Full Production Journey

While material selection and printing are crucial steps, the production of inflatable arches involves many more stages, each contributing to the final product’s quality and functionality.

Design and Engineering: Where Ideas Take Shape

- Client Consultation: We work closely with clients to understand their vision and event requirements.

- 3D Modeling: Our designers create detailed 3D models to visualize the final product.

- Structural Analysis: Engineers ensure the arch design is stable and safe for its intended use.

- Pattern Creation: Precise patterns are developed for cutting the fabric pieces.

Cutting and Assembly: Precision in Every Stitch

- Computer-Aided Cutting: Fabric is cut using advanced machinery for accuracy.

- Reinforcement Application: High-stress areas receive additional reinforcement.

- Seam Sealing: For waterproof arches, seams are carefully sealed.

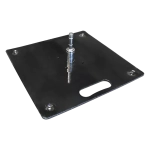

- Inflation System Integration: Blowers or air pumps are matched to the arch’s size and intended use.

Quality Control: Ensuring Excellence

- Air Pressure Testing: Each arch is inflated to check for leaks and structural integrity.

- Print Quality Inspection: Designs are scrutinized for color accuracy and alignment.

- Hardware Check: All zippers, valves, and anchoring points are tested.

- Final Appearance Review: The arch is fully set up for a comprehensive visual inspection.

The ASAP CANOPY Advantage: Speed, Versatility, and Reliability

At ASAP CANOPY, we’ve refined our production process to offer unparalleled benefits to our clients:

- Rapid Deployment: Our inflatable arches can be set up in just 5 minutes, saving valuable time at events.

- All-Season Performance: Whether it’s a sunny summer day or a chilly winter evening, our arches stand tall.

- Customization King: From size to shape to design, we offer extensive customization options.

- Durability Champion: Built to last, our arches maintain their appearance and functionality through multiple uses.

Conclusion: Elevating Events with Inflatable Excellence

The production of inflatable arches at ASAP CANOPY is more than just a manufacturing process – it’s a commitment to excellence, innovation, and customer satisfaction. By combining premium materials, cutting-edge printing technologies, and meticulous craftsmanship, we create inflatable arches that don’t just meet expectations – they exceed them.

Whether you’re planning a marathon finish line, a grand store opening, or a festival entrance, our inflatable arches are designed to make a lasting impression. With ASAP CANOPY, you’re not just getting a product; you’re investing in an experience – one that begins with the first inflate and continues through countless successful events.

Ready to elevate your next event with a custom inflatable arch? Contact ASAP CANOPY today, and let’s bring your vision to life!

5×5 Pop Up Tent

5×5 Pop Up Tent 6.5×6.5 Pop Up Tent

6.5×6.5 Pop Up Tent 10×10 Canopy Tent

10×10 Canopy Tent 10×15 Canopy Tent

10×15 Canopy Tent 10×20 Canopy Tent

10×20 Canopy Tent Canopy Options

Canopy Options Blank Canopy Top

Blank Canopy Top Canopy Top

Canopy Top Canopy Walls

Canopy Walls Canopy Side Skirt

Canopy Side Skirt Blank Canopy

Blank Canopy Blank Canopy Kit

Blank Canopy Kit

Inflatable Canopy Tents 10×10

Inflatable Canopy Tents 10×10 Inflatable Canopy Tents 13×13

Inflatable Canopy Tents 13×13 Inflatable Canopy Tents 16×16

Inflatable Canopy Tents 16×16 Inflatable Canopy Tents 20×20

Inflatable Canopy Tents 20×20 Inflatable Canopy Tents 23×23

Inflatable Canopy Tents 23×23 Inflatable Canopy Tents 26×26

Inflatable Canopy Tents 26×26 Inflatable Spider Tents

Inflatable Spider Tents Inflatable Dome Tents

Inflatable Dome Tents Inflatable Eclipse Tents

Inflatable Eclipse Tents Inflatable Party Tent

Inflatable Party Tent Inflatable Furniture

Inflatable Furniture Inflatable Pillar

Inflatable Pillar

Single Pole Star Tents

Single Pole Star Tents Double Pole Star Tents

Double Pole Star Tents

15FT Inflatable Arches

15FT Inflatable Arches 20FT Inflatable Arches

20FT Inflatable Arches 25FT Inflatable Arches

25FT Inflatable Arches 30FT Inflatable Arches

30FT Inflatable Arches 40FT Inflatable Arches

40FT Inflatable Arches 50FT Inflatable Arches

50FT Inflatable Arches Custom Constant Arches

Custom Constant Arches Custom Sealed Arches

Custom Sealed Arches

Fitted Table Covers

Fitted Table Covers Stretch-Fit Table Covers

Stretch-Fit Table Covers Loose Table Throws

Loose Table Throws Cross-Over Stretch-Fit Table Cover

Cross-Over Stretch-Fit Table Cover Round Stretch-Fit Table Cover

Round Stretch-Fit Table Cover Blank Table Throws

Blank Table Throws 3-Sided Loose Table Throw

3-Sided Loose Table Throw Round Fitted Table Covers

Round Fitted Table Covers Table Runners

Table Runners Square Table Covers

Square Table Covers

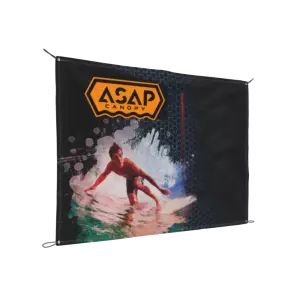

Feather Flags

Feather Flags Blade Flags

Blade Flags Feather Banner

Feather Banner Blade Banner

Blade Banner Teardrop Flags

Teardrop Flags Teardrop Banner

Teardrop Banner Rectangle Flags

Rectangle Flags Rectangle Banner

Rectangle Banner Mesh Event Banners

Mesh Event Banners Pop Out Banner Horizontal

Pop Out Banner Horizontal Pop-Out Banner Vertical

Pop-Out Banner Vertical

Trade Show Display

Trade Show Display Trade Show Display Kit

Trade Show Display Kit Pop Up Trade Show Display

Pop Up Trade Show Display Pop Up Trade Show Display Deluxe Kit

Pop Up Trade Show Display Deluxe Kit Pop Up Trade Show Display Kit

Pop Up Trade Show Display Kit TableTop Displays Kit

TableTop Displays Kit Pop Up Tabletop Display Kit

Pop Up Tabletop Display Kit Pop Up Tabletop Display

Pop Up Tabletop Display Tabletop Display

Tabletop Display Straight Trade Show Exhibit Booth

Straight Trade Show Exhibit Booth Banner Stand

Banner Stand

Tent Accessories

Tent Accessories Flag Accessories

Flag Accessories Arch Accessories

Arch Accessories Trade Show Accessories

Trade Show Accessories