Why ASAP Canopy stands out as the leader in Canopy manufacturing

When it comes to protective shelter solutions, canopy tents need to offer durability, reliability and responsiveness, no matter the challenge. ASAP Canopy’s unique combination of custom manufacturing, quality materials and forward-thinking innovation drives its dominance as the premier canopy producer for today’s most demanding large-scale projects.

When durability and reliability matter most, let’s explore the key areas that make this American-made canopy tent manufacturer the top choice for everyone from Fortune 500 companies to the military.

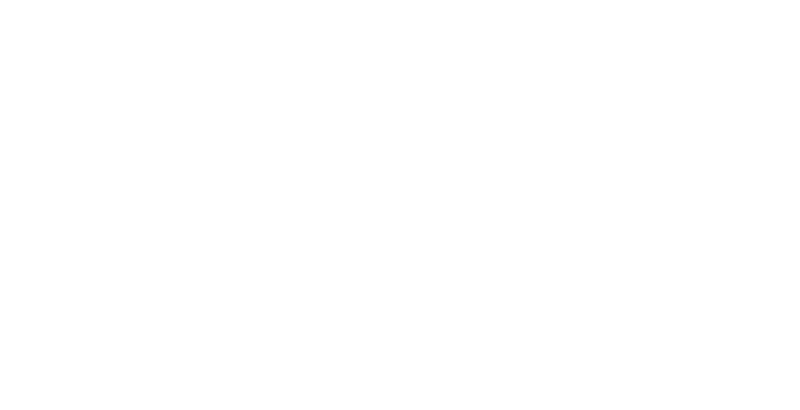

Unparalleled customization capabilities

With 150,000 square feet of state-of-the-art manufacturing infrastructure in Dongguan, California and Dongguan, China, ASAP Canopy can provide custom canopy tent projects of virtually any size while maintaining rapid speeds. Their completely in-house aluminum forming construction process allows for specialized construction without the need to rely on outside suppliers.

This helps create structures 20 feet to 300 feet wide to meet unique requirements—from suspended lighting fixtures to integrated water-collection roof panels. Their industrial-grade CNC press brakes and ID sawing machinery increase part accuracy, allowing complexity to be realized faster.

With extensive on-site printing capabilities, ASAP can apply custom colors in any hue or finish, even for small batch requests, without having to wait months for an offshore supplier. Whether generating 400 identical frames or offering four different powder finishes in five connected shells, ASAP makes it easy to control variation programmatically.

In 2021 alone, more than 2,000 organizations have utilized ASAP’s design team to conceive fully personalized canopy solutions, protecting assets ranging from sensitive defense technology to high-end awards shows. What they have in common? All projects were completed on time and urgent tasks were simply unmatched by competitors relying on overseas.

Speed and agility when it matters most

The combination of domestic facility and process improvements translates into industry-leading build and implementation rates. Even for stock items, outsourced production in China can often guarantee a 1-3 day timeline, and ASAP Canopy can deliver from proof of concept to installation in 12 days.

Their just-in-time manufacturing principles allow onshore steel in California today to be shipped as a ready-to-use custom cap tomorrow. Regional warehousing further increases flexibility, allowing production to be dynamically expanded as demand changes. This proved invaluable when shipping bottlenecks in mid-2021 caused months of delays for most import-reliant manufacturers. ASAP Canopy simply adds domestic manufacturing, protecting partners’ timelines.

In 2022, temporary venues from festivals to summits will still face a squeeze on turnaround times. But even large-scale custom canopy footprint specifications can be fast-tracked through ASAP’s procurement agility—their automated tools can adapt to expedite any request and maintain consistency. This speed enhances quality assurance by monitoring each production milestone directly in-country rather than across oceans.

Obsession with advances in materials science

In addition to manufacturing bandwidth, ASAP Canopy invests heavily in materials research and development, translating into best-in-class protected spaces. Their engineers are constantly pioneering upgraded metals, coatings and fabrics to make them perform better in the face of adversity. Latest developments include:

Proprietary Hard Aluminum Alloy – This stronger variant improves structural integrity by nearly 20% over commercial grade steel. Critical for installations facing high winds, heavy snow loads and other stresses. Its unique processing recipe took more than two years to perfect.

Entropik Powder Coating – This liquid-based nanoformulation forms a molecular “skin” that resists corrosion longer than standard powder coatings while maintaining its finish over decades of sun, salt and moisture exposure. Surface gloss.

600D Polyester Material – combines woven and non-woven textures to provide increased water resistance and light blocking that is not possible with basic vinyl. Each layer adapts to the insulation properties and transparency of the lighting fixture.

In-house control of these material innovations from conceptualization to application in our own labs and production lines in California means there are no outsourcing markups and faster technology iterations. This enables the delivery of state-of-the-art cockpit experiences in categories such as military or motorsport year after year – customers simply won’t settle for less.

Fanatical quality control

With full production ownership, a near-strict quality assurance policy verifies every square inch of coverage to perfection. Patented inspection system finds the smallest metal burrs or fabric defects before shipment. The support team even assists end users with proper on-site installation to optimize safety and pressure dynamics based on geographic location.

This sense of responsibility from start to finish translates into lasting peace of mind that only a fully integrated manufacturer like ASAP Canopy can achieve. Projects are not just imported into containers that are missing critical testing touchpoints across procurement steps.

And capacity is growing – their recent investment of $4 million in alloy cast gear is designed to add a further 190 tonnes of basic steel supply per month as domestic demand diversifies. This upstream oversight will further improve consistency while increasing employment opportunities.

Dominate the market in terms of quantity

While public companies report revenue transparently, private companies often keep performance metrics secret. Still, some data illustrates ASAP Canopy’s growing industry footprint:

120% – Commercial square footage increase in California from 2020 to 2021 to support scaled manufacturing and powder coating demand

8,100% – CAGR of orders for large-format custom canopies, significantly exceeding the market average in the durable goods industry

$410 million – U.S. temporary canopy producers are expected to be valued at $410 million in 2025 as demand climbs across industries

17% – ASAP Canopy’s current share of aftermarket heavy-duty canopy sales to commercial operators, construction companies and event companies

With numerous high-profile partnerships and extensive growth signaling deep market penetration, ASAP Canopy has solidified its reputation as the definitive canopy manufacturer in the United States. Their balance of smart expansion and process discipline has attracted buyers — especially amid the recent supply instability and offshore unknowns.

Trusted by family agencies

Major consumer brands turn to ASAP Canopy to drive resiliency and style in shelters that fully reflect the needs of their occupants. Canopy tent infrastructure protects some of the country’s most visible destinations:

The Grove Promenade – This Los Angeles shopping mecca, which welcomes 22 million visitors annually, is protected by an ASAP installation that combines durability with an eye-catching appearance. Stylish activities take advantage of park flexibility securely mounted overhead.

Atlantis Casino, Bahamas – Luxurious oceanfront hotel relies on ASAP’s canvas composites, which thanks to a proprietary nano-treatment, can withstand wind gusts of 150 mph during tropical cyclones. Even in extreme conditions, guests stay dry under ASAP’s extended biopolymer-coated sunshades.

USVA Championships – Top sports talent looks to cover durability for fans with disabilities as ASAP units withstand the abuse of balls, gear and extreme weather game after game at major professional tennis tournaments while demonstrating professionalism during global broadcasts .

LG Fashion Week – Lights, cameras and the need for constant movement The shelter facilitated complex show construction without compromising stability. ASAP Canopy’s modular truss frame provides the flexibility to transform a loading dock into a runway for global exposure overnight with durability-tested anchors.

Redefining Emergency Response Shelters

When critical infrastructure fails, crisis mitigation increasingly relies on rapid deployment of temporary shelters. ASAP Canopy partners with federal and state emergency management agencies to create purpose-built, resilient shelters that benefit communities when they are needed most:

Their hurricane evacuation shelters have double-thickness roofs while integrating solar panels and condensation collection capabilities to aid in survivability in the event of a power/utility outage.

Wildfire command shells allow for smoother coordination of emergency operations when densely populated areas face imminent danger. The rugged filtration system keeps air breathable, helping decision makers manage the unpredictability of combustion.

Pandemic quarantine shelters use coated copper mesh barriers to isolate potentially infected patients, which have been shown to stop the spread of infectious diseases while allowing healthy airflow.

During industrial threats and geopolitical attacks, chemical/radiation shielding canopy tents safely contain contaminated civilians using an advanced liquid-impermeable skin barrier tested to be effective by civil defense authorities.

ASAP Canopy also has backup disaster mobilization agreements with partners such as the Red Cross and the Salvation Army to rapidly deploy emergency shelters in the event of a regional impact.

Canopy tent manufacturer – Values Beyond the Bottom Line

But Made in America means a deeper commitment to ethical and ecological innovation, laying the foundation for conscientious capitalism. ASAP Canopy has implemented lean clean manufacturing principles, reducing scrap by 70% since 2018 while concentrating highly recyclable aluminum and steel streams. They continue to research renewable bioplastics and plant-based composites to completely eliminate fossil fuels from future assembly lines.

Rooting in California means giving back to community foundations that address local issues like homelessness, workforce development and sustainable agriculture. ASAP Canopy’s corporate social responsibility program positively impacts volunteer hours and donations of dedicated weather relief shelters to improve lives throughout our hometown.

This focus beyond profitability earned ASAP Canopy a distinguished sustainability award, positioning it as an ESG leader – actively driving change around the world.

A preferred partner now and into the future ASAP Canopy has earned the trust of organizations and institutions demanding uncompromising shelter by checking every box – consistent quality, responsive agility to scale, dynamic technology innovation and richness across operations Compassion and responsibility.

Their 150,000 square foot factory center drives revolutionary manufacturing where it would be impossible to source piecemeal components from outside. It helps imagine and create the world’s most visionary canopy enclosures, executed in record time – transforming dreams into protected realities that are consistent regardless of size.

From initial conception to installation and future maintenance inspections, clients are guided to build lasting relationships that transcend the transaction. An obsession with advanced materials and modular environmental systems means there are endless possibilities for the shelter’s responsive development over the years.

So with unparalleled bespoke expertise ensuring valuables are protected within the strongest, smartest canopy shelters, ASAP leads the industry into the future. They provide assurance today while innovating a revolutionary safe haven for tomorrow.

5×5 Pop Up Tent

5×5 Pop Up Tent 6.5×6.5 Pop Up Tent

6.5×6.5 Pop Up Tent 10×10 Canopy Tent

10×10 Canopy Tent 10×15 Canopy Tent

10×15 Canopy Tent 10×20 Canopy Tent

10×20 Canopy Tent Canopy Options

Canopy Options Blank Canopy Top

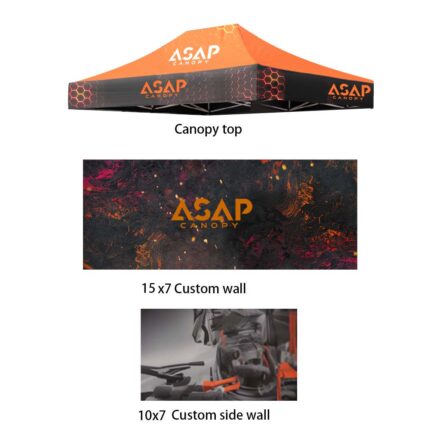

Blank Canopy Top Canopy Top

Canopy Top Canopy Walls

Canopy Walls Canopy Side Skirt

Canopy Side Skirt Blank Canopy

Blank Canopy Blank Canopy Kit

Blank Canopy Kit

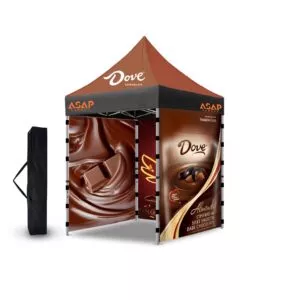

Inflatable Canopy Tents 10×10

Inflatable Canopy Tents 10×10 Inflatable Canopy Tents 13×13

Inflatable Canopy Tents 13×13 Inflatable Canopy Tents 16×16

Inflatable Canopy Tents 16×16 Inflatable Canopy Tents 20×20

Inflatable Canopy Tents 20×20 Inflatable Canopy Tents 23×23

Inflatable Canopy Tents 23×23 Inflatable Canopy Tents 26×26

Inflatable Canopy Tents 26×26 Inflatable Spider Tents

Inflatable Spider Tents Inflatable Dome Tents

Inflatable Dome Tents Inflatable Eclipse Tents

Inflatable Eclipse Tents Inflatable Party Tent

Inflatable Party Tent Inflatable Furniture

Inflatable Furniture Inflatable Pillar

Inflatable Pillar

Single Pole Star Tents

Single Pole Star Tents Double Pole Star Tents

Double Pole Star Tents

15FT Inflatable Arches

15FT Inflatable Arches 20FT Inflatable Arches

20FT Inflatable Arches 25FT Inflatable Arches

25FT Inflatable Arches 30FT Inflatable Arches

30FT Inflatable Arches 40FT Inflatable Arches

40FT Inflatable Arches 50FT Inflatable Arches

50FT Inflatable Arches Custom Constant Arches

Custom Constant Arches Custom Sealed Arches

Custom Sealed Arches

Fitted Table Covers

Fitted Table Covers Stretch-Fit Table Covers

Stretch-Fit Table Covers Loose Table Throws

Loose Table Throws Cross-Over Stretch-Fit Table Cover

Cross-Over Stretch-Fit Table Cover Round Stretch-Fit Table Cover

Round Stretch-Fit Table Cover Blank Table Throws

Blank Table Throws 3-Sided Loose Table Throw

3-Sided Loose Table Throw Round Fitted Table Covers

Round Fitted Table Covers Table Runners

Table Runners Square Table Covers

Square Table Covers

Feather Flags

Feather Flags Blade Flags

Blade Flags Feather Banner

Feather Banner Blade Banner

Blade Banner Teardrop Flags

Teardrop Flags Teardrop Banner

Teardrop Banner Rectangle Flags

Rectangle Flags Rectangle Banner

Rectangle Banner Mesh Event Banners

Mesh Event Banners Pop Out Banner Horizontal

Pop Out Banner Horizontal Pop-Out Banner Vertical

Pop-Out Banner Vertical

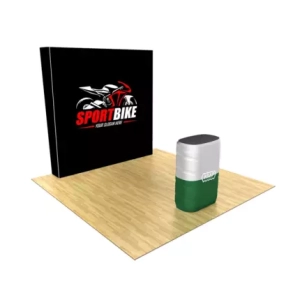

Trade Show Display

Trade Show Display Trade Show Display Kit

Trade Show Display Kit Pop Up Trade Show Display

Pop Up Trade Show Display Pop Up Trade Show Display Deluxe Kit

Pop Up Trade Show Display Deluxe Kit Pop Up Trade Show Display Kit

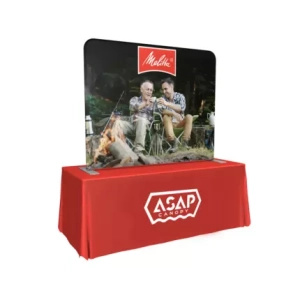

Pop Up Trade Show Display Kit TableTop Displays Kit

TableTop Displays Kit Pop Up Tabletop Display Kit

Pop Up Tabletop Display Kit Pop Up Tabletop Display

Pop Up Tabletop Display Tabletop Display

Tabletop Display Straight Trade Show Exhibit Booth

Straight Trade Show Exhibit Booth Banner Stand

Banner Stand

Tent Accessories

Tent Accessories Flag Accessories

Flag Accessories Arch Accessories

Arch Accessories Trade Show Accessories

Trade Show Accessories